Indoor, Construction, Building

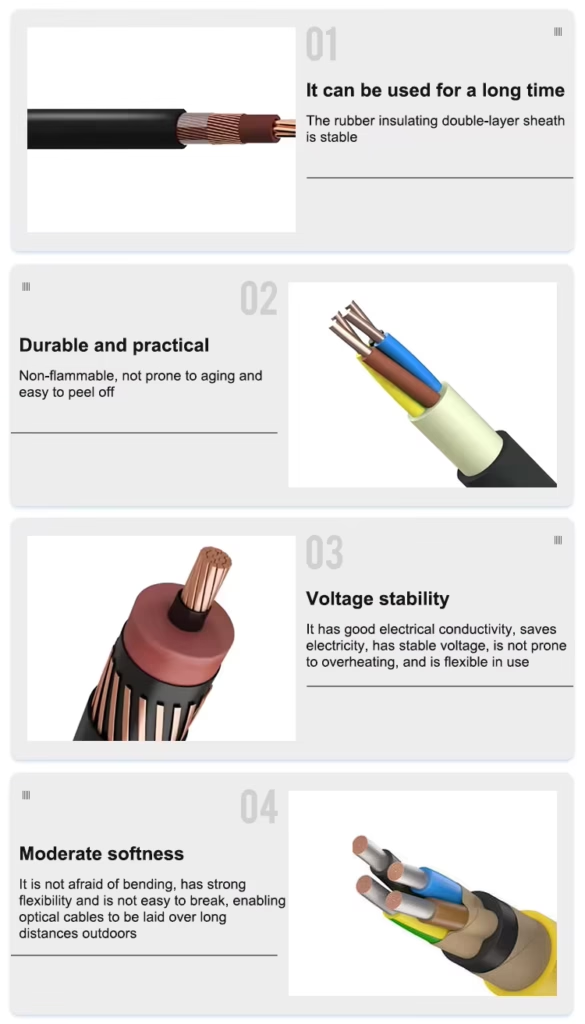

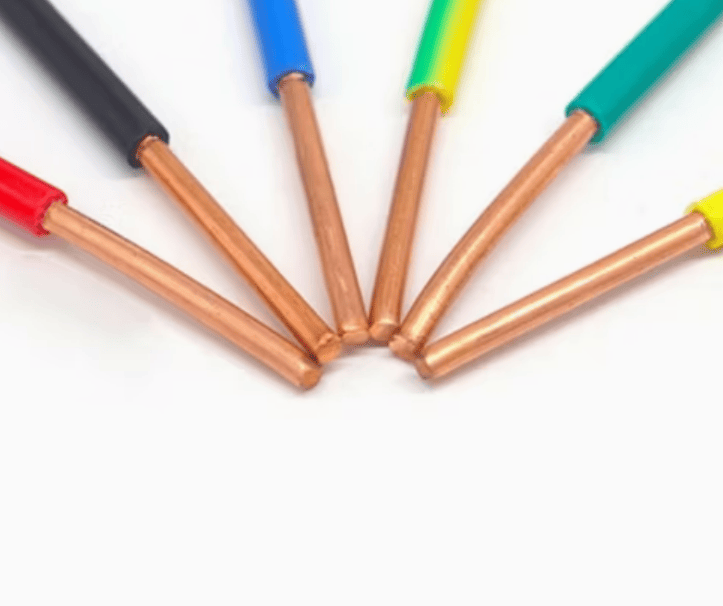

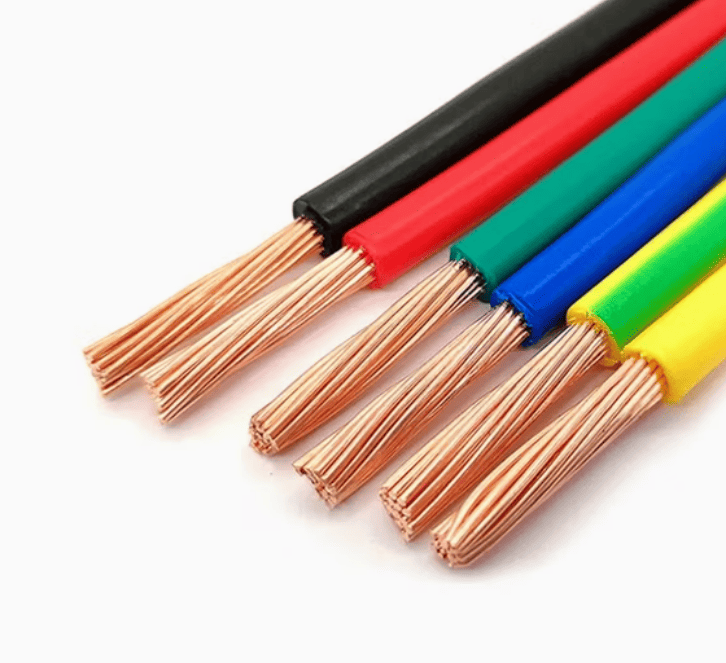

This 600-volt electrical wire is suitable for general power and lighting applications.

- Application: For use in residential, commercial, and industrial buildings.

- Voltage & Location: Rated for circuits up to 600V in both wet and dry locations.

- Temperature Ratings:

- Type TW: 60°C

- Type THW: 75°C

- Type THW2: 95°C

- Key Certifications: UL-listed as flame-retardant (VW-1), oil-resistant, and (for larger sizes) sunlight-resistant and suitable for use in cable trays.

- Construction: Made with a bare copper conductor and printed PVC insulation.

Product Overview

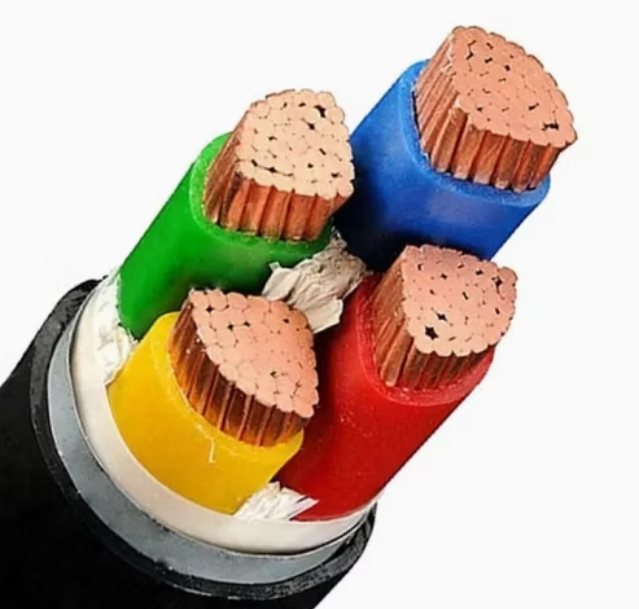

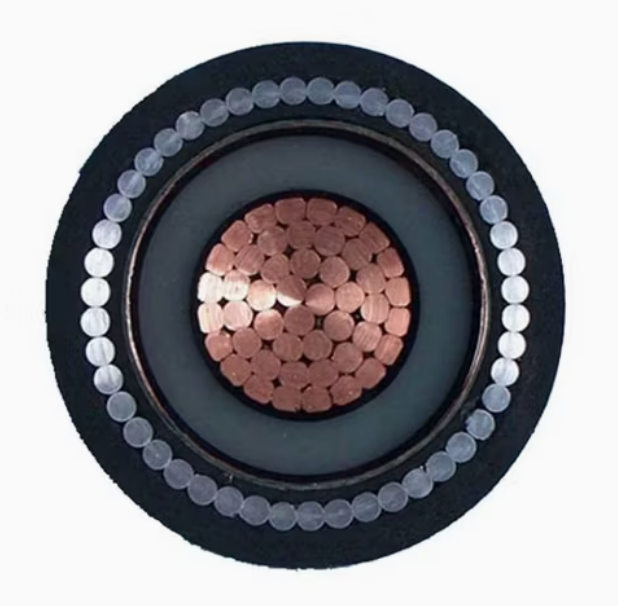

This cable is designed for transmitting electrical power in alternating current (AC) systems with a frequency of 50Hz and a maximum rated voltage of 36kV. It is suitable for a wide range of applications, including indoor installations in power supply stations and switchboards, as well as outdoor use in cable ducts, direct burial, and on cable trays across industrial and power generation facilities.

Key Specifications

Rated Voltages:

The cable is available in several voltage ratings, including 3.6/6kV, 6/10kV, 8.7/15kV, 12/20kV, and 18/30kV.

Cable Construction:

- Conductor: Class 2 stranded circular or compacted circular, available in copper or aluminum.

- Conductor Screen: A semi-conductive layer.

- Insulation: Cross-Linked Polyethylene (XLPE).

- Insulation Screen: A semi-conductive layer.

- Metallic Screen: Composed of copper wires, a copper tape, or a combination of both.

- Inner Sheath: Polyvinyl Chloride (PVC).

- Armouring: Steel Tape Armoured (SWA). For single-core cables, a non-magnetic armouring material is used.

- Outer Sheath: Polyvinyl Chloride (PVC).

Manufacturing Process:

The conductor screen, XLPE insulation, and insulation screen are manufactured simultaneously using a triple extrusion process on a Continuous Vulcanization Line. This advanced method ensures pristine interfaces between the layers, which guarantees a construction free from Partial Discharge and delivers high operational reliability.

Main Technical Parameters

1) Conductor DC Resistance:

The maximum DC resistance of the conductor at 20°C is provided in the table below for various cross-sectional areas, for both copper (tinned and non-tinned) and aluminum conductors.

2) Partial Discharge Test:

All cables undergo a partial discharge test. The test voltage and the maximum permissible discharge magnitude (10 pC) for each voltage rating are detailed in the accompanying table.

3) AC Voltage Test:

Each cable is subjected to an AC withstand voltage test. The specific test voltage and duration (5 minutes) for each voltage rating are listed in the table.

4) Available Configurations:

The table provided outlines the available nominal cross-sectional areas (in mm²) and the number of cores for each rated voltage.

Technical Data Tables

Table 1-1: Maximum DC Resistance at 20°C (Ω/km)

| Cross-Section (mm²) | 16 | 25 | 35 | 50 | 70 | 95 | 120 | 150 |

|---|---|---|---|---|---|---|---|---|

| Copper (Non-Tinned) | 1.15 | 0.727 | 0.524 | 0.387 | 0.268 | 0.193 | 0.153 | 0.124 |

| Copper (Tinned) | 1.16 | 0.734 | 0.529 | 0.391 | 0.270 | 0.195 | 0.154 | 0.126 |

| Aluminum | 1.91 | 1.20 | 0.868 | 0.641 | 0.443 | 0.320 | 0.253 | 0.206 |

| Cross-Section (mm²) | 185 | 240 | 300 | 400 | 500 | 630 | 800 | 1000 |

| Copper (Non-Tinned) | 0.0991 | 0.0754 | 0.0601 | 0.0470 | 0.0366 | 0.0283 | 0.0221 | 0.0176 |

| Copper (Tinned) | 0.100 | 0.0762 | 0.0607 | 0.0475 | 0.0369 | 0.0286 | 0.0224 | 0.0177 |

| Aluminum | 0.164 | 0.125 | 0.100 | 0.0778 | 0.0605 | 0.0469 | 0.0367 | 0.0291 |

Table 1-2: Partial Discharge Test

| Rated Voltage (kV) | 3.6/6 | 6/10 | 8.7/15 | 12/20 | 18/30 | 21/35 | 26/35 |

|---|---|---|---|---|---|---|---|

| Test Voltage (kV) | 6.23 | 10.38 | 15.05 | 20.76 | 31.14 | 36.33 | 44.98 |

| Max. Discharge (pC) | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

Table 1-3: AC Voltage Withstand Test

| Rated Voltage (kV) | 3.6/6 | 6/10 | 8.7/15 | 12/20 | 18/30 | 21/35 | 26/35 |

|---|---|---|---|---|---|---|---|

| Test Voltage (kV) | 12.5 | 21 | 30.5 | 42 | 63 | 73.5 | 91 |

| Test Time (min) | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

Table 1-4: Rated Voltage, Core Numbers & Cross-Sectional Area

| U0/Um (kV) | 3.6/6 | 6/10 | 8.7/15 | 12/20 | 18/30 | 21/35 | 26/35 |

|---|---|---|---|---|---|---|---|

| Single-Core (mm²) | 25-630 | 25-630 | 35-630 | 35-630 | 50-630 | 50-630 | 50-630 |

| Three-Core (mm²) | 25-400 | 25-400 | 35-400 | 35-400 | 50-400 | 50-400 | 50-400 |

Cable Parameter

| 14 | 1 | 0.030 | 0.76 | 0.169 | 4.3 | 22 | 33 |

| 12 | 1 | 0.030 | 0.76 | 0.189 | 4.8 | 32 | 47 |

| 10 | 1 | 0.030 | 0.76 | 0.213 | 5.4 | 46 | 68 |

| 6 | 1 | 0.060 | 1.52 | 0.276 | 7 | 101 | 151 |

| 14 | 7 | 0.030 | 0.76 | 0.177 | 4.5 | 24 | 36 |

| 12 | 7 | 0.030 | 0.76 | 0.201 | 5.1 | 34 | 50 |

| 10 | 7 | 0.030 | 0.76 | 0.228 | 5.8 | 49 | 73 |

| 8 | 7 | 0.045 | 1.14 | 0.291 | 7.4 | 79 | 118 |

| 4 | 7 | 0.060 | 1.52 | 0.386 | 9.8 | 172 | 256 |

| 2 | 7 | 0.080 | 2.03 | 0.445 | 11.3 | 263 | 391 |

| 1 | 19 | 0.080 | 2.03 | 0.531 | 13.5 | 339 | 505 |

| 1/0 | 19 | 0.080 | 2.03 | 0.575 | 14.6 | 418 | 622 |

| 2/0 | 19 | 0.080 | 2.03 | 0.622 | 15.8 | 515 | 767 |

| 3/0 | 19 | 0.080 | 2.03 | 0.677 | 17.2 | 638 | 950 |

| 250 | 37 | 0.095 | 2.41 | 0.823 | 20.9 | 943 | 1404 |

| 300 | 37 | 0.095 | 2.41 | 0.882 | 22.4 | 1118 | 1664 |

| 350 | 37 | 0.095 | 2.41 | 0.937 | 23.8 | 1292 | 1923 |

| 400 | 37 | 0.095 | 2.41 | 0.984 | 25 | 1465 | 2180 |

| 500 | 61 | 0.095 | 2.41 | 1.079 | 27.4 | 1810 | 2694 |

| 600 | 61 | 0.110 | 2.79 | 1.197 | 30.4 | 2178 | 3241 |

| 800 | 61 | 0.110 | 2.79 | 1.343 | 34.1 | 2863 | 4260 |

| 1000 | 61 | 0.110 | 2.79 | 1.472 | 37.4 | 3538 | 5265 |

0.6/1kv LV Copper Aluminum Conductor

Indoor, Construction, Building UL CSA Electrical Twu Wire0.6/1kv LV Copper Aluminum Conductor8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC, RoHS,…

8.7/15 (17.5) Kv Copper/ Aluminum Conductor Three Core XLPE Insulated Cts Unarmored Cable

Indoor, Construction, Building UL CSA Electrical Twu Wire8.7/15 (17.5) Kv Copper/ Aluminum Conductor Three Core…

AS/NZS 5000 Single Core SDI Cable Cu/PVC/PVC Building Wire 50mm2

Indoor, Construction, Building UL CSA Electrical Twu WireAS/NZS 5000 Single Core SDI Cable Cu/PVC/PVC Building…

Construction Cable Single Core Building Wire SDI Electrical Wire 1.5mm2

Indoor, Construction, Building UL CSA Electrical Twu WireConstruction Cable Single Core Building Wire SDI Electrical…

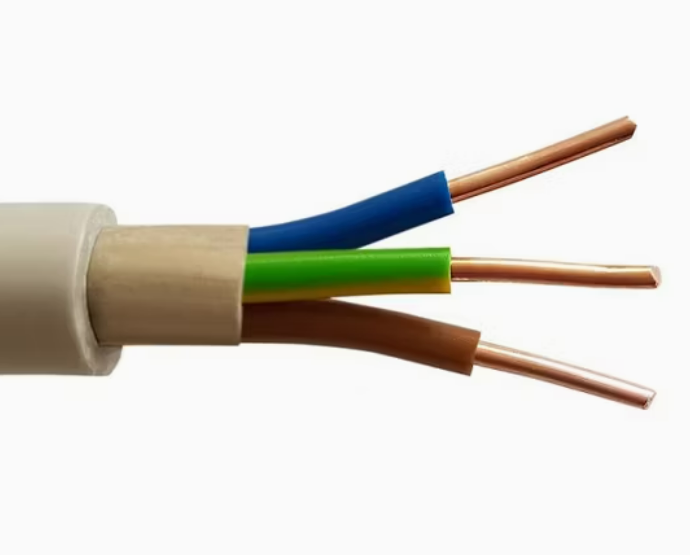

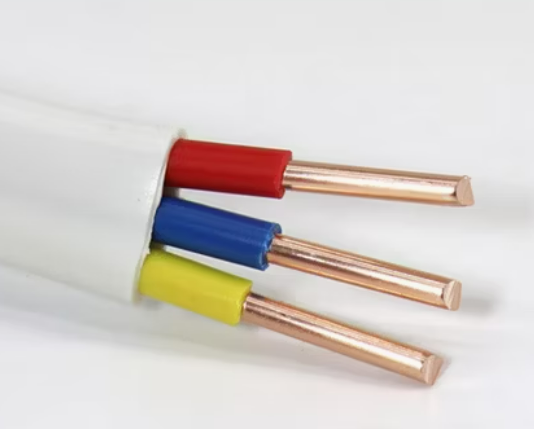

3 Cores Electrical Cable Wire with Solid Copper Conductor 450 / 750V with PVC Sheath

Indoor, Construction, Building UL CSA Electrical Twu WirePVC Coated Flexible Flat Electrical TPS Cable Wire8AWG,10AWG,12AWG,14AWGISO9001,…

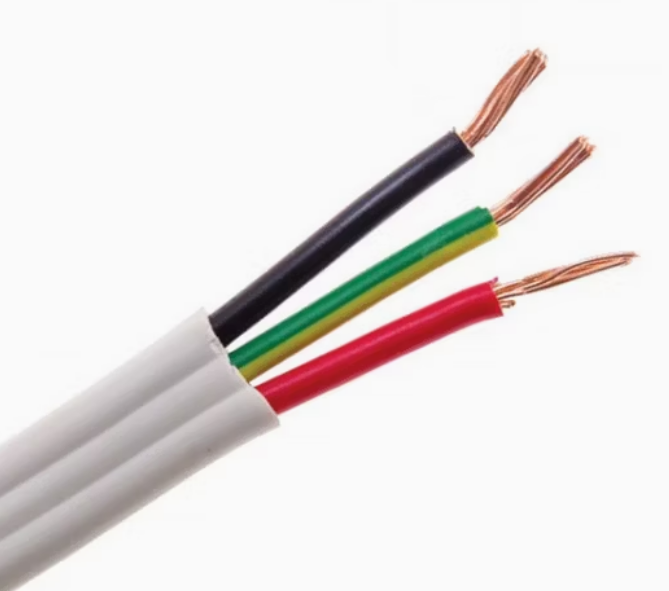

PVC Coated Flexible Flat Electrical TPS Cable Wire

Indoor, Construction, Building UL CSA Electrical Twu WirePVC Coated Flexible Flat Electrical TPS Cable Wire8AWG,10AWG,12AWG,14AWGISO9001,…

0.6/1kv LV Copper Aluminum Conductor

Indoor, Construction, Building UL CSA Electrical Twu Wire0.6/1kv LV Copper Aluminum Conductor8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC, RoHS,…

8.7/15 (17.5) Kv Copper/ Aluminum Conductor Three Core XLPE Insulated Cts Unarmored Cable

Indoor, Construction, Building UL CSA Electrical Twu Wire8.7/15 (17.5) Kv Copper/ Aluminum Conductor Three Core…

AS/NZS 5000 Single Core SDI Cable Cu/PVC/PVC Building Wire 50mm2

Indoor, Construction, Building UL CSA Electrical Twu WireAS/NZS 5000 Single Core SDI Cable Cu/PVC/PVC Building…

Construction Cable Single Core Building Wire SDI Electrical Wire 1.5mm2

Indoor, Construction, Building UL CSA Electrical Twu WireConstruction Cable Single Core Building Wire SDI Electrical…

3 Cores Electrical Cable Wire with Solid Copper Conductor 450 / 750V with PVC Sheath

Indoor, Construction, Building UL CSA Electrical Twu WirePVC Coated Flexible Flat Electrical TPS Cable Wire8AWG,10AWG,12AWG,14AWGISO9001,…

PVC Coated Flexible Flat Electrical TPS Cable Wire

Indoor, Construction, Building UL CSA Electrical Twu WirePVC Coated Flexible Flat Electrical TPS Cable Wire8AWG,10AWG,12AWG,14AWGISO9001,…

PVC Coated Flexible Flat Electrical TPS Cable Wire

Indoor, Construction, Building UL CSA Electrical Twu Wire70mm2 1c Aluminum Single Core XLPE PVC 1kv…

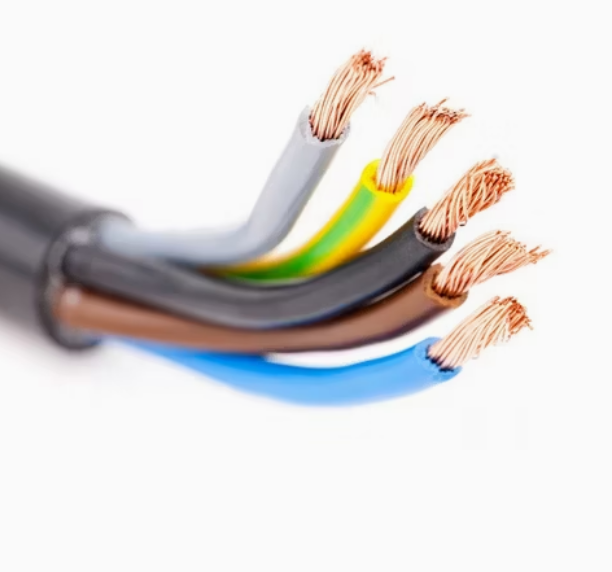

Copper Core PVC Coated Flexible Flat Electrical TPS Cable Wire

Indoor, Construction, Building UL CSA Electrical Twu Wire2.5mm2 4mm2 Flat Twin Cable Red and Black…

2.5mm2 4mm2 Flat Twin Cable Red and Black Copper Wire

Indoor, Construction, Building UL CSA Electrical Twu WireAS/NZS 5000.1 Building Wire Single Insulated 1core 10mm…

CE BVVB Bvr BV Flexible Copper 2 Core or 2+ Earth PVC Electrical Building Twin Flat Wire

Indoor, Construction, Building UL CSA Electrical Twu WirePVC Insulated Covered Fire Resistant Wire for Home…

PVC Insulated Covered Fire Resistant Wire for Home Building

Indoor, Construction, Building UL CSA Electrical Twu WirePVC Insulated Covered Fire Resistant Wire for Home…

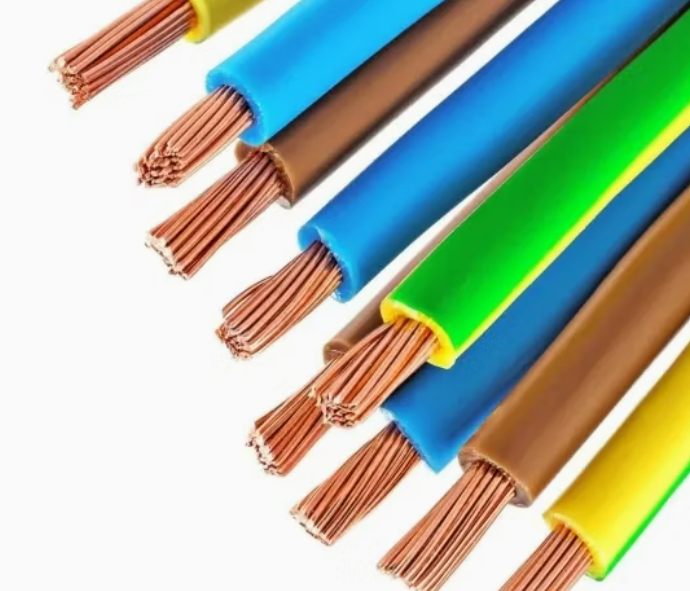

Customize Single Insulated 1core 95mm V-90 PVC Blue

Indoor, Construction, Building UL CSA Electrical Twu WireCustomize Single Insulated 1core 95mm V-90 PVC Blue8AWG,10AWG,12AWG,14AWGISO9001,…

AS/NZS 5000.1 Building Wire Single Insulated 1core 95mm V-90 PVC Red

Indoor, Construction, Building UL CSA Electrical Twu WireAS/NZS 5000.1 Building Wire Single Insulated 1core 95mm…

6mm 10mm Single Core Copper PVC Cable and Wire Price

Indoor, Construction, Building UL CSA Electrical Twu Wire1.5mm 2.5mm 4mm Single Core Copper PVC House…

1.5mm 2.5mm 4mm Single Core Copper PVC House Wiring Electrical Cable

Indoor, Construction, Building UL CSA Electrical Twu Wire1.5mm 2.5mm 4mm Single Core Copper PVC House…

16mm2 Multicore Copper Wire PVC Electrical Wire

Indoor, Construction, Building UL CSA Electrical Twu Wire16mm2 Multicore Copper Wire PVC Electrical Wire8AWG,10AWG,12AWG,14AWGISO9001, CE,…

450/750V 2.5mm2 4mm2 6mm2 10mm Cable

Indoor, Construction, Building UL CSA Electrical Twu Wire450/750V 2.5mm2 4mm2 6mm2 10mm Cable8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC,…

Al/XLPE/Cts/Swa/PVC Cable

Indoor, Construction, Building UL CSA Electrical Twu WireAl/XLPE/Cts/Swa/PVC Cable8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC, RoHS, UL CSAWhatsapp: +86…

Underground Armored Cable

Indoor, Construction, Building UL CSA Electrical Twu WireUnderground Armored Cable8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC, RoHS, UL CSAWhatsapp:…

Copper XLPE Swa Underground Armored Cable

Indoor, Construction, Building UL CSA Electrical Twu WireCopper XLPE Swa Underground Armored Cable8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC,…

0.6/1 Kv Copper Sta or Swa PVC Sheathed Power

Indoor, Construction, Building UL CSA Electrical Twu WirePVC Sheathed Power Cable8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC, RoHS, UL…

Medium Voltage Cable Cu or Al/XLPE/Cts/Swa/PVC Cable

Indoor, Construction, Building UL CSA Electrical Twu WireMedium Voltage Cable8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC, RoHS, UL CSAWhatsapp:…

300V Cable wire

Indoor, Construction, Building UL CSA Electrical Twu Wire300V Cable THW TWU Copper8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC, RoHS,…

600V Cable THW TWU Copper

Indoor, Construction, Building UL CSA Electrical Twu Wire600V Cable THW TWU Copper8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC, RoHS,…