Indoor, Construction, Building

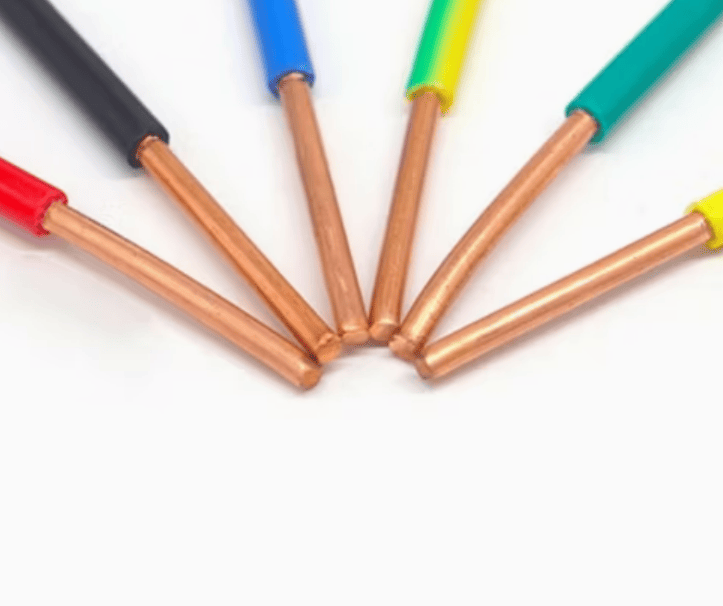

This 600-volt electrical wire is suitable for general power and lighting applications.

- Application: For use in residential, commercial, and industrial buildings.

- Voltage & Location: Rated for circuits up to 600V in both wet and dry locations.

- Temperature Ratings:

- Type TW: 60°C

- Type THW: 75°C

- Type THW2: 95°C

- Key Certifications: UL-listed as flame-retardant (VW-1), oil-resistant, and (for larger sizes) sunlight-resistant and suitable for use in cable trays.

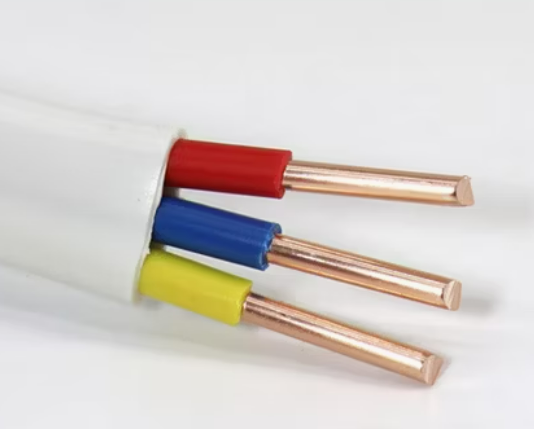

- Construction: Made with a bare copper conductor and printed PVC insulation.

Product Overview

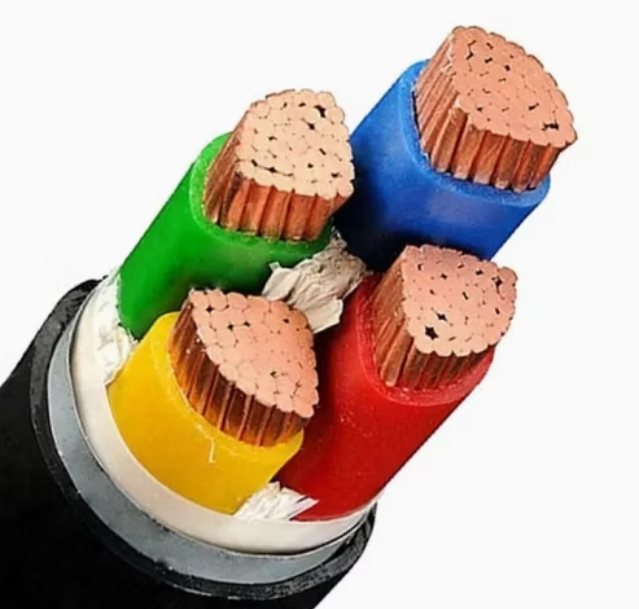

Insulated & Fire-Resistant Power Cables

These PVC-insulated and fire-resistant power cables are designed for permanent installation in power transmission and distribution networks, operating at 50Hz AC with voltages up to 6kV.

Key Specifications:

- Operating Temperature: Maximum continuous conductor temperature of 70°C.

- Short-Circuit Rating: Conductor temperature must not exceed 160°C during a short-circuit event of up to 5 seconds.

- Installation: Can be installed vertically without level restrictions. Minimum ambient temperature for installation is 0°C.

Standard Constructions:

The cables are available in various configurations, including:

- Conductor: Copper or Aluminum (Cu/Al)

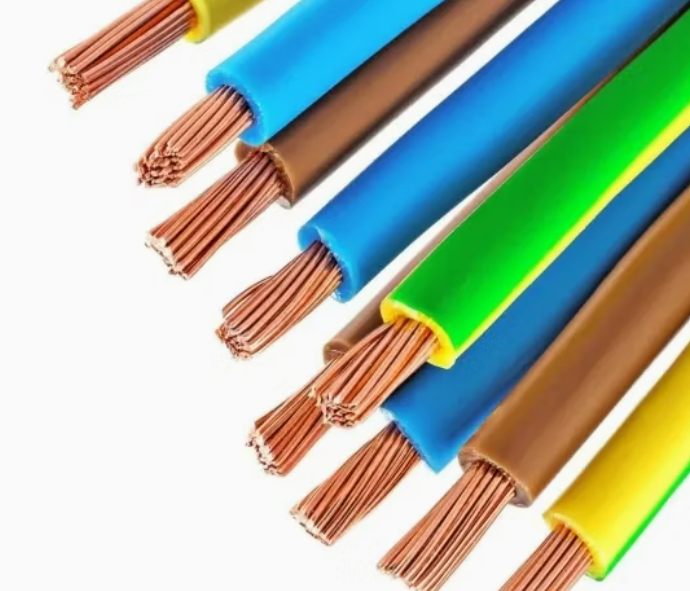

- Insulation: PVC or XLPE

- Armouring: Options include Steel Wire Armour (SWA), Steel Tape Armour (SWT), Aluminum Wire Armour (AWA), and Aluminum Tape Armour (AWT).

- Sheath: PVC

Nominal Conductor Cross-Sectional Areas (mm²):

| Main Core | 3+1 Core | 3+2 Core | 4+1 Core |

|---|---|---|---|

| 4, 6, 10, 16, 25, 35, 50, 70, 95, 120, 150, 185, 240 | 2.5, 4, 6, 10, 16, 16, 25, 35, 50, 70, 70, 95, 120 | 2.5, 4, 6, 10, 16, 16, 25, 35, 50, 70, 70, 95, 120 | 2.5, 4, 6, 10, 16, 16, 25, 35, 50, 70, 70, 95, 120 |

Paraphrased Version

Cable Construction & Technical Specifications

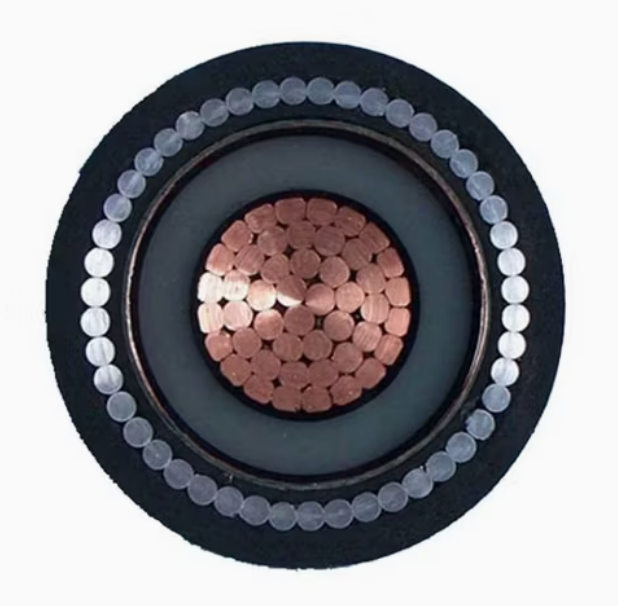

This cable is constructed with a robust, layered design for high performance and reliability.

Layer-by-Layer Construction:

- Metallic Screen: Available in configurations of copper wires, copper tape, or a combination of both.

- Inner Sheath: Composed of PVC (Polyvinyl Chloride).

- Armouring: Features Steel Tape Armour (SWA). For single-core cables, a non-magnetic armour material is used to minimize energy losses.

- Outer Sheath: A durable outer layer of PVC (Polyvinyl Chloride).

Advanced Manufacturing Process:

The core components—the conductor screen, XLPE insulation, and insulation screen—are manufactured using a triple extrusion process on a Continuous Vulcanization Line. This state-of-the-art method ensures:

- Perfectly clean interfaces between the insulation and semiconductive layers.

- A construction that is free from Partial Discharge (PD).

- Exceptionally high operational reliability and longevity.

Key Technical Parameters:

For detailed performance data, please refer to the following tables:

- Table 1-1: Cable conductor DC resistance.

- Table 1-2: Partial discharge test results.

- Table 1-3: AC voltage withstand test specifications.

- Table 1-4: Rated voltage, core numbers, and nominal cross-sectional areas.

Key Improvements in This Version:

Grammar and Spelling: Corrects “Amoured” to “Armouring” and “Semi-Conductive” to the more standard “semiconductive.”

Professional Tone: Uses standard industry language (e.g., “configurations,” “state-of-the-art method,” “robust, layered design”).

Clarity and Flow: Sentences are restructured to be more direct and easier to read.

Logical Grouping: Information is organized under clear headings (Construction, Manufacturing, Parameters).

Explained Benefits: The technical advantage of the “triple extrusion method” is clearly stated (prevents Partial Discharge, ensures reliability).

Technical Data Tables

Table 1-1: Maximum DC Resistance at 20°C (Ω/km)

| Cross-Section (mm²) | 16 | 25 | 35 | 50 | 70 | 95 | 120 | 150 |

|---|---|---|---|---|---|---|---|---|

| Copper (Non-Tinned) | 1.15 | 0.727 | 0.524 | 0.387 | 0.268 | 0.193 | 0.153 | 0.124 |

| Copper (Tinned) | 1.16 | 0.734 | 0.529 | 0.391 | 0.270 | 0.195 | 0.154 | 0.126 |

| Aluminum | 1.91 | 1.20 | 0.868 | 0.641 | 0.443 | 0.320 | 0.253 | 0.206 |

| Cross-Section (mm²) | 185 | 240 | 300 | 400 | 500 | 630 | 800 | 1000 |

| Copper (Non-Tinned) | 0.0991 | 0.0754 | 0.0601 | 0.0470 | 0.0366 | 0.0283 | 0.0221 | 0.0176 |

| Copper (Tinned) | 0.100 | 0.0762 | 0.0607 | 0.0475 | 0.0369 | 0.0286 | 0.0224 | 0.0177 |

| Aluminum | 0.164 | 0.125 | 0.100 | 0.0778 | 0.0605 | 0.0469 | 0.0367 | 0.0291 |

Table 1-2: Partial Discharge Test

| Rated Voltage (kV) | 3.6/6 | 6/10 | 8.7/15 | 12/20 | 18/30 | 21/35 | 26/35 |

|---|---|---|---|---|---|---|---|

| Test Voltage (kV) | 6.23 | 10.38 | 15.05 | 20.76 | 31.14 | 36.33 | 44.98 |

| Max. Discharge (pC) | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

Table 1-3: AC Voltage Withstand Test

| Rated Voltage (kV) | 3.6/6 | 6/10 | 8.7/15 | 12/20 | 18/30 | 21/35 | 26/35 |

|---|---|---|---|---|---|---|---|

| Test Voltage (kV) | 12.5 | 21 | 30.5 | 42 | 63 | 73.5 | 91 |

| Test Time (min) | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

Table 1-4: Rated Voltage, Core Numbers & Cross-Sectional Area

| U0/Um (kV) | 3.6/6 | 6/10 | 8.7/15 | 12/20 | 18/30 | 21/35 | 26/35 |

|---|---|---|---|---|---|---|---|

| Single-Core (mm²) | 25-630 | 25-630 | 35-630 | 35-630 | 50-630 | 50-630 | 50-630 |

| Three-Core (mm²) | 25-400 | 25-400 | 35-400 | 35-400 | 50-400 | 50-400 | 50-400 |

Cable Parameter

| 14 | 1 | 0.030 | 0.76 | 0.169 | 4.3 | 22 | 33 |

| 12 | 1 | 0.030 | 0.76 | 0.189 | 4.8 | 32 | 47 |

| 10 | 1 | 0.030 | 0.76 | 0.213 | 5.4 | 46 | 68 |

| 6 | 1 | 0.060 | 1.52 | 0.276 | 7 | 101 | 151 |

| 14 | 7 | 0.030 | 0.76 | 0.177 | 4.5 | 24 | 36 |

| 12 | 7 | 0.030 | 0.76 | 0.201 | 5.1 | 34 | 50 |

| 10 | 7 | 0.030 | 0.76 | 0.228 | 5.8 | 49 | 73 |

| 8 | 7 | 0.045 | 1.14 | 0.291 | 7.4 | 79 | 118 |

| 4 | 7 | 0.060 | 1.52 | 0.386 | 9.8 | 172 | 256 |

| 2 | 7 | 0.080 | 2.03 | 0.445 | 11.3 | 263 | 391 |

| 1 | 19 | 0.080 | 2.03 | 0.531 | 13.5 | 339 | 505 |

| 1/0 | 19 | 0.080 | 2.03 | 0.575 | 14.6 | 418 | 622 |

| 2/0 | 19 | 0.080 | 2.03 | 0.622 | 15.8 | 515 | 767 |

| 3/0 | 19 | 0.080 | 2.03 | 0.677 | 17.2 | 638 | 950 |

| 250 | 37 | 0.095 | 2.41 | 0.823 | 20.9 | 943 | 1404 |

| 300 | 37 | 0.095 | 2.41 | 0.882 | 22.4 | 1118 | 1664 |

| 350 | 37 | 0.095 | 2.41 | 0.937 | 23.8 | 1292 | 1923 |

| 400 | 37 | 0.095 | 2.41 | 0.984 | 25 | 1465 | 2180 |

| 500 | 61 | 0.095 | 2.41 | 1.079 | 27.4 | 1810 | 2694 |

| 600 | 61 | 0.110 | 2.79 | 1.197 | 30.4 | 2178 | 3241 |

| 800 | 61 | 0.110 | 2.79 | 1.343 | 34.1 | 2863 | 4260 |

| 1000 | 61 | 0.110 | 2.79 | 1.472 | 37.4 | 3538 | 5265 |

0.6/1kv LV Copper Aluminum Conductor

Indoor, Construction, Building UL CSA Electrical Twu Wire0.6/1kv LV Copper Aluminum Conductor8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC, RoHS,…

8.7/15 (17.5) Kv Copper/ Aluminum Conductor Three Core XLPE Insulated Cts Unarmored Cable

Indoor, Construction, Building UL CSA Electrical Twu Wire8.7/15 (17.5) Kv Copper/ Aluminum Conductor Three Core…

AS/NZS 5000 Single Core SDI Cable Cu/PVC/PVC Building Wire 50mm2

Indoor, Construction, Building UL CSA Electrical Twu WireAS/NZS 5000 Single Core SDI Cable Cu/PVC/PVC Building…

Construction Cable Single Core Building Wire SDI Electrical Wire 1.5mm2

Indoor, Construction, Building UL CSA Electrical Twu WireConstruction Cable Single Core Building Wire SDI Electrical…

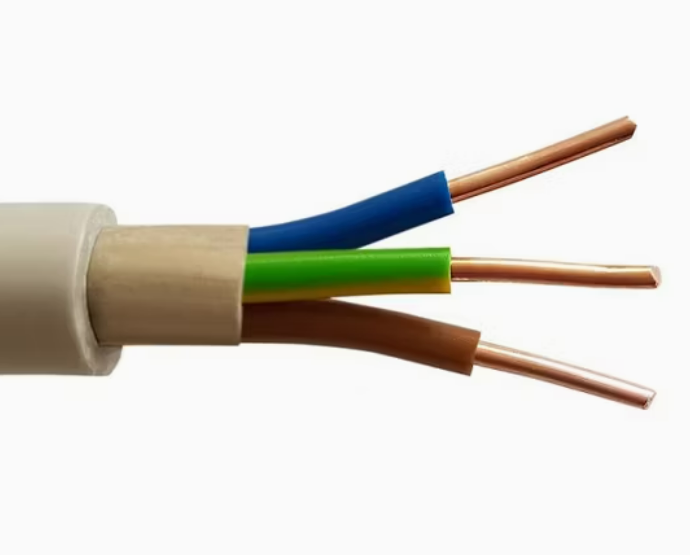

3 Cores Electrical Cable Wire with Solid Copper Conductor 450 / 750V with PVC Sheath

Indoor, Construction, Building UL CSA Electrical Twu WirePVC Coated Flexible Flat Electrical TPS Cable Wire8AWG,10AWG,12AWG,14AWGISO9001,…

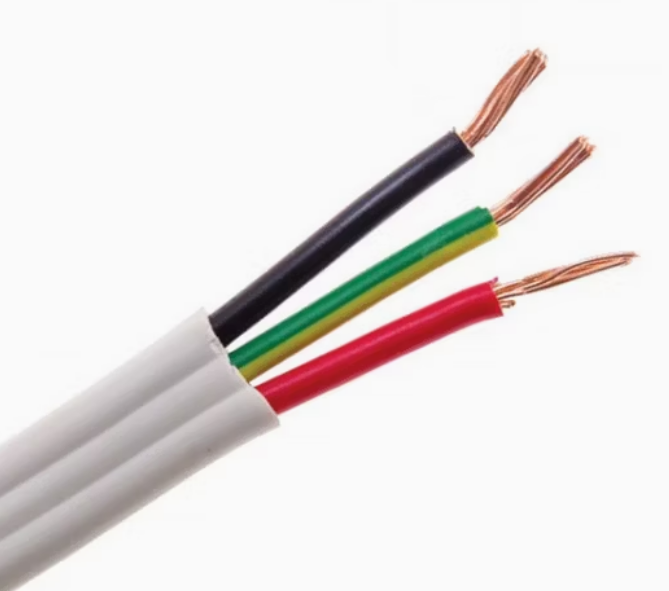

PVC Coated Flexible Flat Electrical TPS Cable Wire

Indoor, Construction, Building UL CSA Electrical Twu WirePVC Coated Flexible Flat Electrical TPS Cable Wire8AWG,10AWG,12AWG,14AWGISO9001,…

PVC Coated Flexible Flat Electrical TPS Cable Wire

Indoor, Construction, Building UL CSA Electrical Twu Wire70mm2 1c Aluminum Single Core XLPE PVC 1kv…

Copper Core PVC Coated Flexible Flat Electrical TPS Cable Wire

Indoor, Construction, Building UL CSA Electrical Twu Wire2.5mm2 4mm2 Flat Twin Cable Red and Black…

2.5mm2 4mm2 Flat Twin Cable Red and Black Copper Wire

Indoor, Construction, Building UL CSA Electrical Twu WireAS/NZS 5000.1 Building Wire Single Insulated 1core 10mm…

CE BVVB Bvr BV Flexible Copper 2 Core or 2+ Earth PVC Electrical Building Twin Flat Wire

Indoor, Construction, Building UL CSA Electrical Twu WirePVC Insulated Covered Fire Resistant Wire for Home…

PVC Insulated Covered Fire Resistant Wire for Home Building

Indoor, Construction, Building UL CSA Electrical Twu WirePVC Insulated Covered Fire Resistant Wire for Home…

Customize Single Insulated 1core 95mm V-90 PVC Blue

Indoor, Construction, Building UL CSA Electrical Twu WireCustomize Single Insulated 1core 95mm V-90 PVC Blue8AWG,10AWG,12AWG,14AWGISO9001,…

AS/NZS 5000.1 Building Wire Single Insulated 1core 95mm V-90 PVC Red

Indoor, Construction, Building UL CSA Electrical Twu WireAS/NZS 5000.1 Building Wire Single Insulated 1core 95mm…

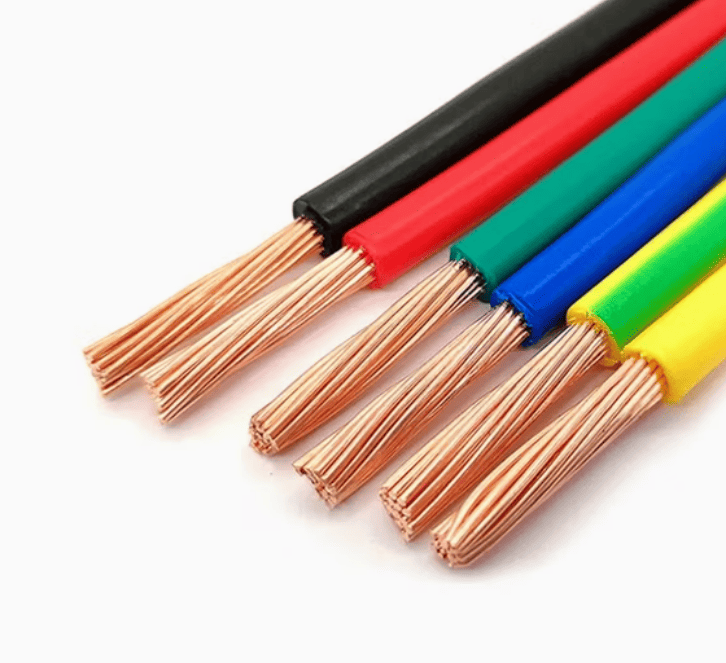

6mm 10mm Single Core Copper PVC Cable and Wire Price

Indoor, Construction, Building UL CSA Electrical Twu Wire1.5mm 2.5mm 4mm Single Core Copper PVC House…

1.5mm 2.5mm 4mm Single Core Copper PVC House Wiring Electrical Cable

Indoor, Construction, Building UL CSA Electrical Twu Wire1.5mm 2.5mm 4mm Single Core Copper PVC House…

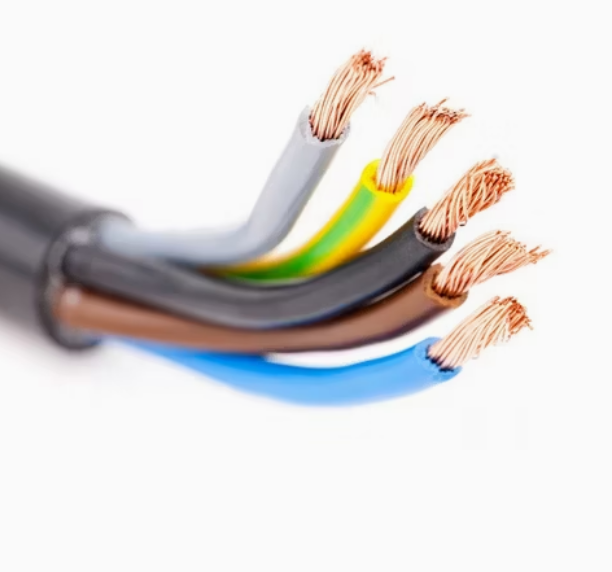

16mm2 Multicore Copper Wire PVC Electrical Wire

Indoor, Construction, Building UL CSA Electrical Twu Wire16mm2 Multicore Copper Wire PVC Electrical Wire8AWG,10AWG,12AWG,14AWGISO9001, CE,…

450/750V 2.5mm2 4mm2 6mm2 10mm Cable

Indoor, Construction, Building UL CSA Electrical Twu Wire450/750V 2.5mm2 4mm2 6mm2 10mm Cable8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC,…

Al/XLPE/Cts/Swa/PVC Cable

Indoor, Construction, Building UL CSA Electrical Twu WireAl/XLPE/Cts/Swa/PVC Cable8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC, RoHS, UL CSAWhatsapp: +86…

Underground Armored Cable

Indoor, Construction, Building UL CSA Electrical Twu WireUnderground Armored Cable8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC, RoHS, UL CSAWhatsapp:…

Copper XLPE Swa Underground Armored Cable

Indoor, Construction, Building UL CSA Electrical Twu WireCopper XLPE Swa Underground Armored Cable8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC,…

0.6/1 Kv Copper Sta or Swa PVC Sheathed Power

Indoor, Construction, Building UL CSA Electrical Twu WirePVC Sheathed Power Cable8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC, RoHS, UL…

Medium Voltage Cable Cu or Al/XLPE/Cts/Swa/PVC Cable

Indoor, Construction, Building UL CSA Electrical Twu WireMedium Voltage Cable8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC, RoHS, UL CSAWhatsapp:…

300V Cable wire

Indoor, Construction, Building UL CSA Electrical Twu Wire300V Cable THW TWU Copper8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC, RoHS,…

600V Cable THW TWU Copper

Indoor, Construction, Building UL CSA Electrical Twu Wire600V Cable THW TWU Copper8AWG,10AWG,12AWG,14AWGISO9001, CE, CCC, RoHS,…